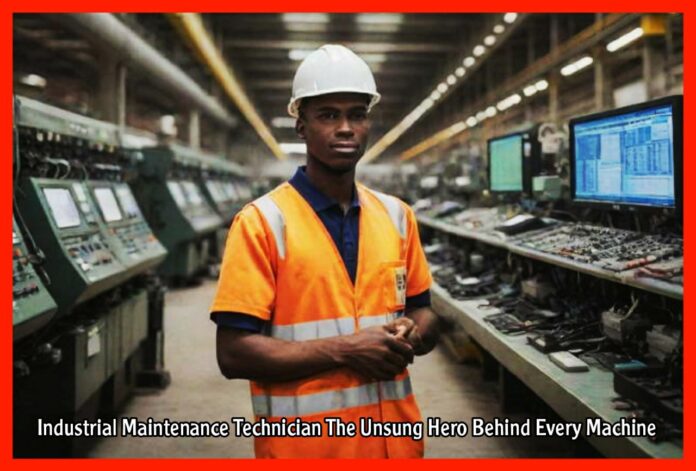

Industrial Maintenance Technician The Unsung Hero Behind Every Machine

“Without maintenance, the machine stops. Without the technician, nothing starts.”

Who Is an Industrial Maintenance Technician?

An Industrial Maintenance Technician is a skilled professional responsible for keeping manufacturing equipment, machinery, and systems running smoothly. They don’t just fix what’s broken — they predict, prevent, and perfect.

Think of them as the backstage crew at a rock concert:

No technician, no show.

What Do They Actually Do?

Here’s a peek into the toolkit of their daily grind:

-

Inspecting machines for signs of wear or malfunction

-

Diagnosing and repairing electrical, mechanical, and hydraulic issues

-

Performing routine maintenance to avoid unscheduled downtime

-

Installing new equipment and ensuring it’s calibrated correctly

-

Keeping records of repairs and service reports

“Industrial Maintenance Techs don’t wait for things to break — they see the future and fix it before it fails.”

Skills That Separate the Pros from the Amateurs

These technicians aren’t just wrench-slingers — they’re problem-solving ninjas with a multimeter in one hand and a laptop in the other.

Here are the top skills they need:

-

Mechanical Aptitude

-

Electrical Knowledge

-

Computerized Maintenance Management Systems (CMMS) familiarity

-

Problem-solving under pressure

-

Reading blueprints & schematics

Why This Job Is Hot Right Now

In a post-COVID world, automation is booming — and someone has to keep the robots alive.

According to recent stats, the demand for industrial maintenance technicians is expected to grow by 13% by 2030, outpacing many other skilled trades.

High job security

Competitive salaries

Opportunities in every industry from food to aerospace

How to Become an Industrial Maintenance Technician

No fluff — just a straightforward roadmap:

1. Get Educated

Enroll in a technical school or community college offering programs in industrial maintenance, mechatronics, or a related field.

2. Get Hands-On

Look for apprenticeships or entry-level roles that let you get dirty (and experienced).

3. Get Certified

Stand out with certifications like:

-

Certified Maintenance & Reliability Technician (CMRT)

-

OSHA safety certifications

-

HVAC/R, PLC, or Robotics training

Future-Proofing the Technician’s Role

As Industry 4.0 transforms manufacturing, the role of technicians is becoming more digital:

-

Predictive analytics via sensors

-

Augmented reality (AR) tools for remote repairs

-

AI-powered diagnostic software

-

Robotics integration

“The technician of the future doesn’t fear robots — they train them.”

Real Voices: A Day in the Life

“You’ve got to love the chaos. One moment you’re welding, the next you’re solving a PLC issue. No two days are the same.”

— Jordan R., Industrial Maintenance Tech, Milwaukee

Industrial Maintenance Technicians Matter

-

They’re the glue holding the industrial world together

-

The job is challenging, rewarding, and future-proof

-

Great pay, tons of demand, and always something new to learn

The next time you walk through a grocery store, board a plane, or open a can of soda — thank an industrial maintenance technician. They’re out there, fixing what we never knew was broken.